Abstract: With the development of science and technology, LED work lights have become increasingly prominent in the lighting industry. Compared with traditional lighting equipment, they have shown significant advantages in terms of energy efficiency, service life, environmental protection, safety of use and cost-effectiveness. Next, this article will deeply analyze LED work lights and their working mechanism, and explore the differences between them and conventional lighting solutions from multiple dimensions such as energy saving effect, life span, positive impact on the environment and cost-effectiveness. Our goal is to make readers more clearly aware of the many benefits of choosing LED work lights compared to traditional lighting.

Table of Contents

1. Introduction to LED work lights

LED work lights are ideal for working in dark or hard-to-reach areas due to their bright light source. Not only are they highly portable, easy to carry and install, but they also utilize efficient LED technology to ensure efficient use of energy. This not only significantly reduces long-term operating costs, but also helps reduce carbon emissions, making them more environmentally friendly.

2. Basic knowledge of lighting

2.1 Principle of LED work light

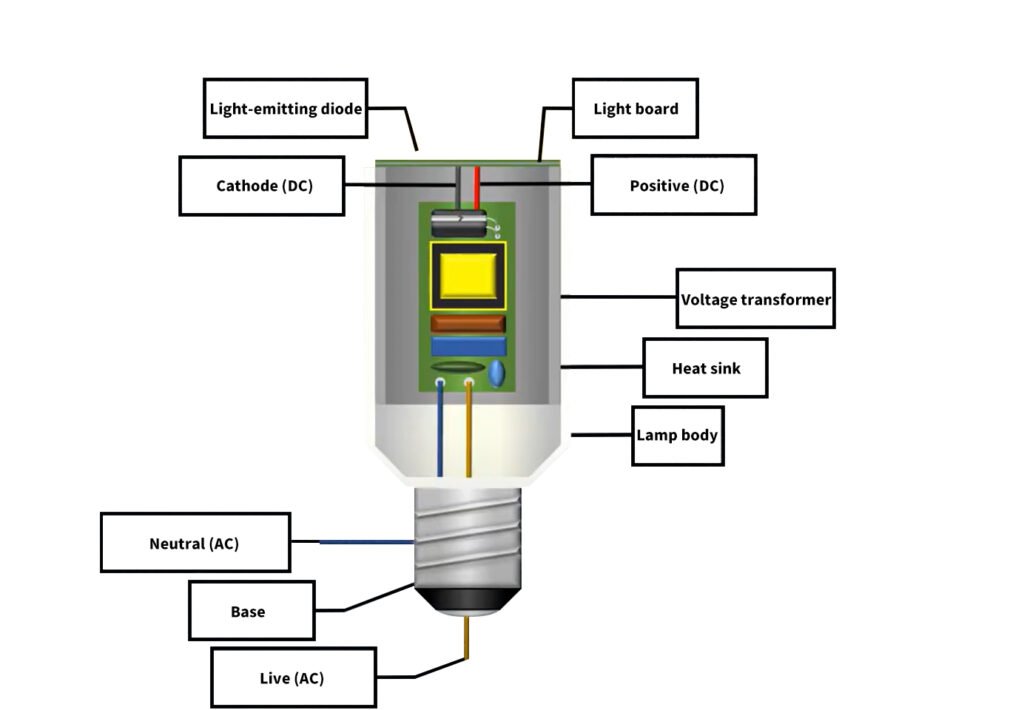

LED stands for light emitting diode. When we turn on the switch, the power will enter from the base like other light bulbs. Household electricity is hundreds of volts of alternating current, while light emitting diodes generally only need one to three volts of direct current, so a transformer driver must be installed in the middle of the bulb. It will convert the higher voltage alternating current into low voltage direct current, and then input the direct current into the light board to make the light emitting diode glow.

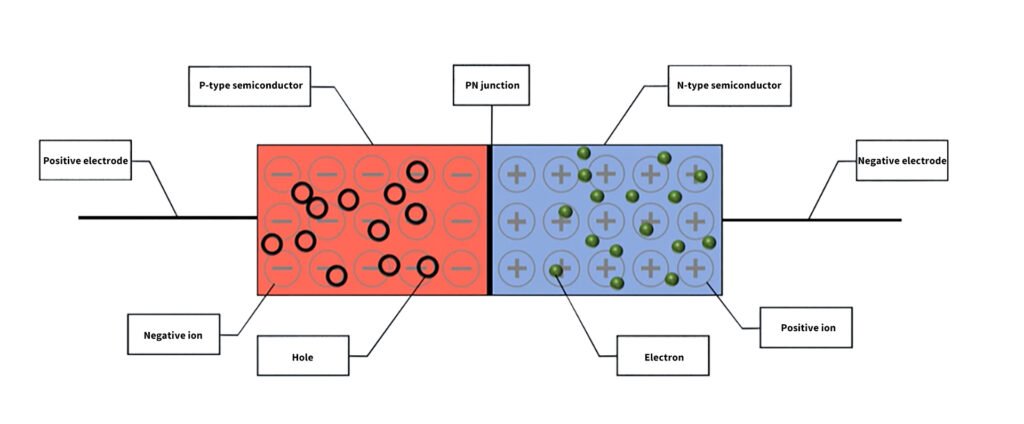

Light-emitting diodes are similar to ordinary diodes. They are made of semiconductor chips, with the two ends connected to the positive and negative electrodes respectively. They all have unidirectional conductivity. The chips of light-emitting diodes contain P-type semiconductors and N-type semiconductors respectively. The middle layer is called PN junction. P-type semiconductors have a large number of positive holes and fixed negative ions, while N-type semiconductors have a large number of negative electrons and fixed positive ions. When the positive electrode receives a positive voltage, the P-type holes will flow to the N-type, and the N-type electrons will flow to the P-type. The holes and electrons meet and combine near the PN junction. In this process, the electrons release the remaining energy in the form of light.

2.2 Luminous flux and lumen

The energy that a light source radiates to the surrounding space per unit time and causes vision is called luminous flux. In physical systems, luminous flux uses an integrating sphere to measure the light emitted by a light source within a solid angle unit. The unit of luminous flux is lumen, which is the transliteration of the English word lumen, abbreviated as lm. The luminous flux radiated from an area of 5.305*10³cm² by an absolute black body at the solidification temperature of platinum is 1lm. 1 lumen = the luminous flux emitted by a point light source with a luminous intensity of 1 candela per unit solid angle.

2.3 Relationship between luminous flux and lighting

The "brightness" we usually perceive should be called "illuminance" to be exact. Illuminance is the luminous flux received by the illuminated surface per unit area, and the unit is lux.

1 lux = the illuminance produced by a point light source with a luminous intensity of 1 candela on a sphere with a radius of 1 meter.

1 lux = 1 lumen of luminous flux evenly distributed over an area of 1 square meter

The relationship between illumination and luminous flux is: illumination = luminous flux/illuminated area.

2.3 Conversion between lumens and watts

Regarding current LED lamps, according to data from this year, the upper limit of their brightness is about 80 lm/W, with a common range of 50 to 70 lm/W. In contrast, incandescent lamps are less efficient, usually between 10 and 15 lm/W, while energy-saving lamps are at the level of 50 to 80 lm/W. Therefore, a 1W LED lamp can be comparable to an incandescent lamp of about 5W, and has similar performance to energy-saving lamps. This comparison is based on the article "Development Trends in Lighting Sources" in the August issue of "Architectural Electrical".

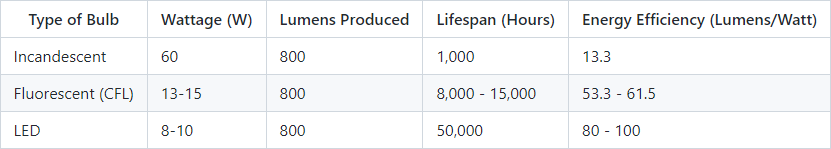

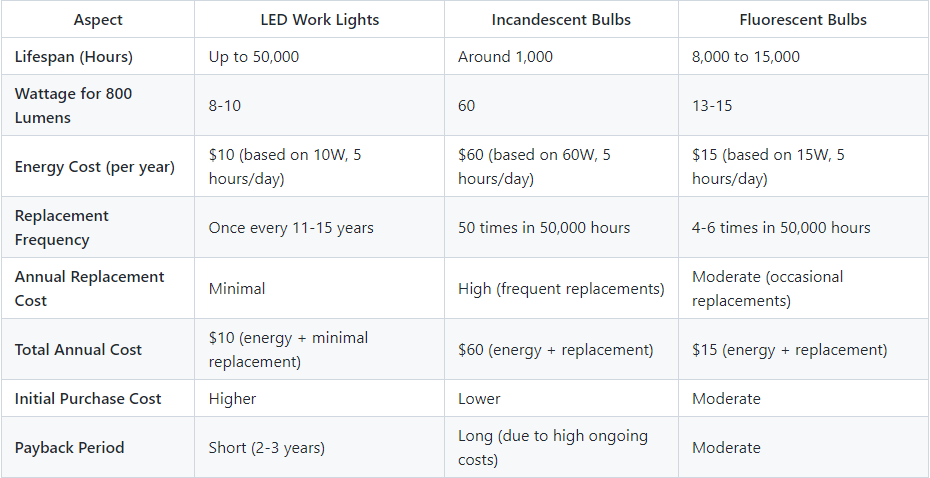

3. LED work lights have better energy efficiency

As can be seen from the table, to produce the same 800 lumens of light flux, incandescent lamps need to reach 60 watts of power, and their energy efficiency is only 13.3%, while fluorescent lamps only need to reach 13-15 watts of power, and the energy consumption rate is 53.3%-61.5%. Among them, LEDs are the most energy-efficient, and 800 lumens of light flux can be achieved with only 8-10 watts of power, and their energy consumption rate is as high as 80%-100%.

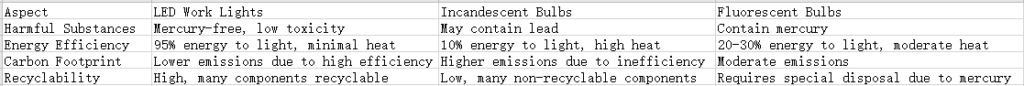

Compared to fluorescent and LED lights, incandescent lamps convert about 10% of the energy they consume into light, and the other 90% is wasted as heat. Fluorescent lamps are slightly more efficient, converting about 20-30% of the energy into light, but still waste a lot of heat. LEDs convert about 95% of the energy into light and only 5% into heat, so they use less energy.

LED work lights consume significantly less power to produce the same luminous flux, so they have better energy efficiency.

4.LED work lights have a longer service life

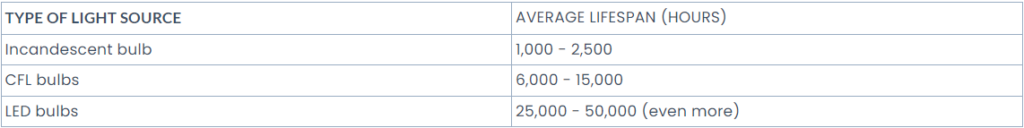

From the data table, we can see that LED bulbs have the longest service life, which can be as high as 25,000-50,000 hours, or even more; CFL bulbs only have 6,000-15,000 hours; and incandescent bulbs have even less, only about 1,000-2,500 hours.

LED lights are completely enclosed in transparent resin and will not break as easily as other bulbs. They are more solid and durable. When using LED work lights, there is no need to replace bulbs frequently. LED lights are not easily affected by frequent switching like energy-saving lamps, and are more suitable for use in environments such as offices or conference rooms.

5. Environmental benefits of LED work lights

LED work lights are an environmentally friendly form of lighting, and many of their components can be recycled, reducing waste and environmental impact at the end of their life cycle. Unlike other lighting sources such as fluorescent and mercury vapor lamps, which contain mercury inside the bulb and require special disposal at the end of the product's life, LED work lights do not require these considerations. LED work lights do not contain toxic substances or emit harmful gases, making them more environmentally friendly.

LED work lights indirectly reduce CO2 emissions from power plants by consuming less power. Incandescent and fluorescent lamps require more energy to operate, resulting in higher carbon emissions. In terms of carbon emissions, LED work lights are also more environmentally friendly.

6. Durability of LED work lights in harsh environments

LED lighting technology is able to maintain its performance over a wide range of temperatures, in stark contrast to traditional lighting systems. Traditional lighting often performs poorly in low temperature environments, requires higher voltage to start, and has reduced brightness. In contrast, LED lighting performs better in cold conditions, is easy to start, and maintains stable brightness. Therefore, LED lighting is very suitable for outdoor environments, cold storage, cold rooms, and surrounding areas of buildings.

LED work lights are completely enclosed in transparent resin and will not break as easily as other glass bulbs, so they are more solid and durable than traditional lighting.

7. Safety of using LED work lights

7.1 Fire and explosion safety

In traditional light bulbs, tungsten filaments are heated or gases are excited to produce light. However, in incandescent bulbs, more than 90% of the electrical energy is converted into heat energy, and only 10% is converted into light energy. This lighting method has obvious risks of overheating and fire. In contrast, LED lights emit light by converting electrical energy into light radiation within semiconductors, avoiding the heating problem, making them a safer option than traditional bulbs. Because LED lights are powered by direct current (DC) low voltage, their DC characteristics improve the stability of the system and reduce the chance of failure. In addition, the circuits of LED lights are more reliable and require less maintenance.

7.2 Better biosafety

Photobiological hazards may arise from infrared or ultraviolet radiation emitted by light sources. Nevertheless, LED lamps do not emit infrared radiation that is harmful to the skin or eyes. On the contrary, fluorescent and incandescent bulbs convert 37% and 73% of their energy consumption into infrared radiation, respectively. In addition, the amount of ultraviolet radiation produced by LED lamps does not exceed 5 uW/lm. In comparison, the ultraviolet radiation of incandescent lamps and compact fluorescent lamps is 70-80 uW/lm and 30-100 uW/lm, respectively. Therefore, it can be concluded that LED lamps are a safe and environmentally friendly choice from a photobiological point of view.

8. Light quality of LED work lights

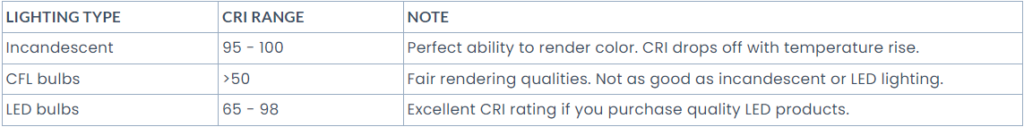

Light color accuracy is measured using the Color Rendering Index (CRI). The higher the CRI rating, the better the color quality the light can provide.

The higher the color rendering index, the clearer the color of objects under the light. From the table data, the color rendering index of incandescent lamps is the best, but its color rendering index will decrease with the increase of temperature, and its energy efficiency is low. Choosing an LED bulb with a higher CRI is obviously a better choice. Bulbs that have obtained ENERGY STAR certification are strictly tested under laboratory conditions. If you are a person who pursues high-quality visual effects, you can buy bulbs that have obtained ENERGY STAR certification and focus on checking their color rendering index.

9. Cost-effectiveness of LED work lights

As can be seen from the figure, the initial cost of purchasing an LED work light is the highest, with a retail cost of $5 or less; fluorescent lamps are second, with a retail cost of about $2; incandescent lamps are the cheapest, with a retail cost of about $1. However, in the long run, using LED work lights will be more cost-effective. The average life of an LED work light is 25,000 hours, and the annual electricity cost is about $1.01. The total cost is expected to be about $28 for more than 25,000 hours of lighting; the annual electricity cost of fluorescent lamps is $2.02, and the number of times the bulb is replaced is about 3 times for 25,000 hours of lighting. With the replacement of bulbs and energy consumption, the total cost of fluorescent lamps for 25,000 hours of lighting is $54; incandescent lamps are the least cost-effective, with an annual electricity cost of about $8.67, and the number of replacements within 25,000 hours is about 20, and the total cost per year for 25,000 hours of use is as high as $219. This is because LED work lights have high energy efficiency and can convert more than 90% of energy into light, which means that with the same luminous flux, LED work lights consume less energy and electricity bills will be lower. However, incandescent lamps and fluorescent lamps have lower energy consumption rates, so the electricity bills will be higher in the later use, and incandescent lamps and fluorescent lamps have shorter service lives and need to be replaced frequently, resulting in higher operating costs.

10.Choosing the right LED work light

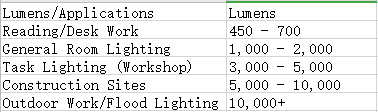

Identify your lighting needs and choose an LED work light with the right lumens according to the table above. The required brightness depends on the application. For tasks that require detailed visibility, such as construction or complex work, higher lumens are required. For general lighting, fewer lumens may be sufficient. Also consider other factors, such as: check the beam angle, color temperature and position to ensure the best lighting conditions.

11. Frequently Asked Questions

11.1Why are LED work lights better?

From the perspective of energy efficiency, service life, safety of use and environmental benefits, LED work lights have more specific advantages than traditional lighting. Although LED work lights have the highest initial cost, in the long run, LED work lights are still the most cost-effective.

11.2 Does the higher the lumen, the brighter the LED work light?

Yes, the higher the lumen (lm) rating, the brighter the LED work light. For example, a 1,000 lumen LED work light will be brighter than a 500 lumen LED work light.

11.3 Will LED work lights damage our eyesight?

Blue LEDs can damage retinal cells and cause vision problems. Therefore, it can damage your vision. However, to avoid these problems, use warm white LEDs and avoid using LED screens at bedtime.

11.4 Does LED save energy?

LED lights are very energy efficient, using minimal electricity without compromising brightness. As a result, they can save 75% to 90% of electricity compared to traditional light sources.

11.5 What happens if the LED current is too high?

If too much current is drawn through an LED, it will try to dissipate as much power as is applied to it. At some stage, it will overheat and self-destruct. This is why it is important to limit the current flowing through an LED.

12 Conclusion

After comparing and analyzing LED work lights with traditional lighting methods, from energy utilization and service life to environmental benefits, safety of use and cost advantages, LED work lights have shown their obvious advantages over traditional lighting. Although the initial investment of LED work lights is high, in the long run, it is undoubtedly wiser to choose LED work lights.

LED lamps represent the latest progress in lighting technology. From many perspectives, choosing LED is undoubtedly a wise decision. If you are interested in professional LED work lights for industrial environments, then there may be options that meet your needs.

-1024x683.jpg)