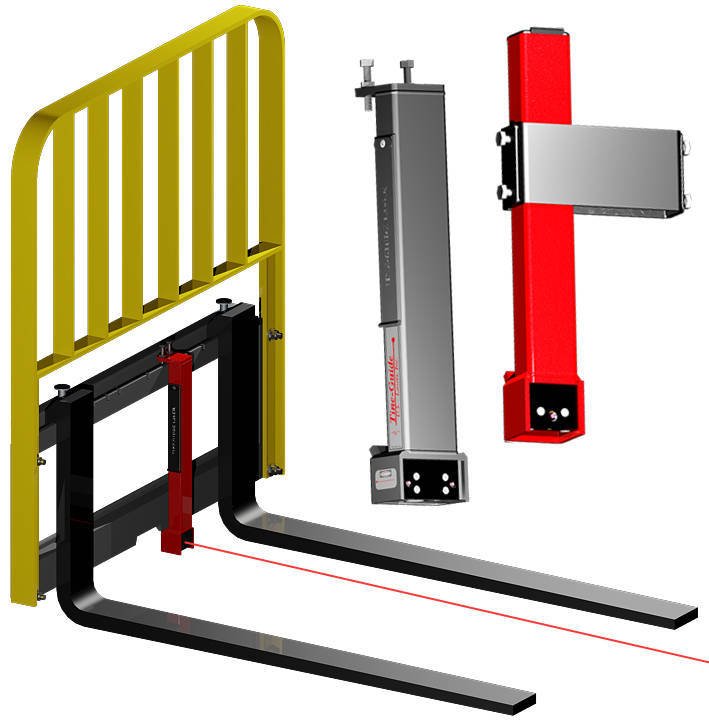

XRL1081PForklift Laser Guide is an advanced tool designed to improve the accuracy of forklift operations. It uses cutting-edge laser technology to help operators achieve accurate height positioning when handling goods, thereby improving handling efficiency.

| Type | Red Laser alignment system |

|---|---|

| Use time per recharge | 50-70hours |

| Full Recharge time | 8hours |

| Laser wavelength | 650mm (red) |

| Laser power | 100mw |

| Laser safety class | III B |

| Working temperature | -20°c – 70°c |

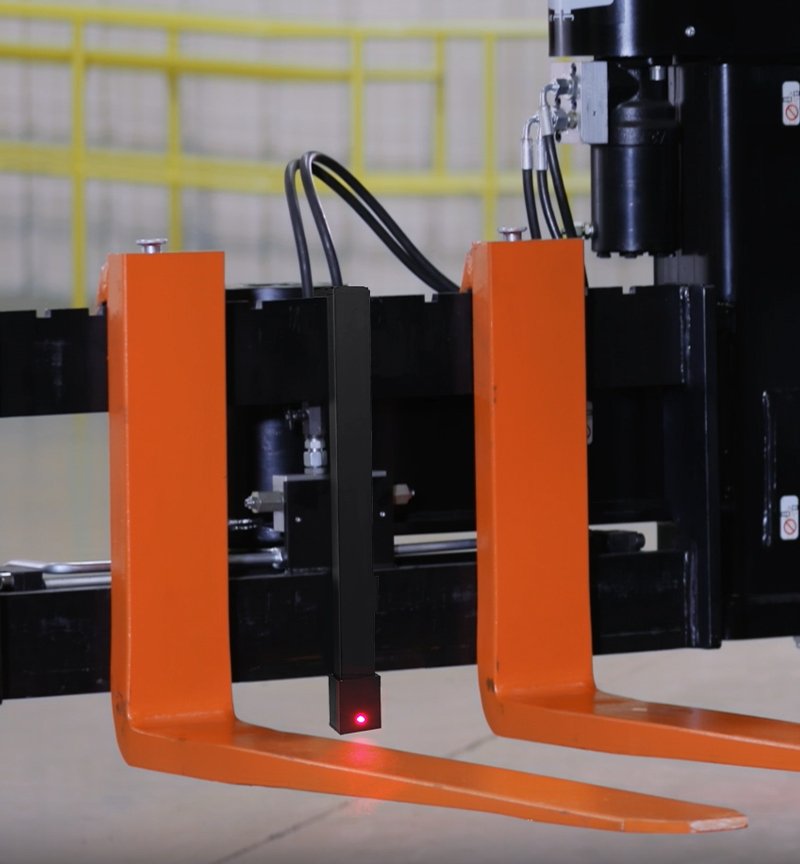

| Configuration | Laser light / battery / magnet |

1.Accurate Fork Placement: The laser guide projects a visible line or beam that helps the operator align the forklift forks with pallet slots or rack beams, ensuring precise placement and reducing the risk of damage to goods and equipment.

2.Improved Safety: By providing clear visual cues, the laser guide helps prevent accidents and collisions, making it easier for operators to navigate tight spaces and avoid obstacles.

3.Increased Efficiency: With better alignment and positioning, forklift operators can perform tasks more quickly and accurately, leading to improved overall productivity in the warehouse.

4.Damage Reduction: The laser guide helps minimize product damage and rack damage by ensuring that the forks are correctly positioned before lifting or placing pallets.

1. Help forklifts insert goods accurately: This line light uses advanced laser technology to help operators achieve precise height positioning when forking goods, accurately insert the forklift arm into the goods, and avoid incorrect insertion and removal due to over-high or under-low positioning

2. Ultra-long use: This line light is equipped with laser lights, batteries and magnets. The battery can be fully charged, and the use time after each full charge is up to 50-70 hours.

3. Comply with laser safety level: The device is equipped with a 650mm wavelength red laser with a power of 100mw and fully complies with Class III B laser safety standards.

4. Strict product quality inspection: The product will undergo strict salt spray testing, high and low temperature testing, aging testing, vibration testing and other tests before shipment to ensure that the product quality strictly meets the requirements.

There is no MOQ here, sufficient inventory, you can buy any quantity you want

Can customize the corresponding Logo according to customer preferences

Provide meticulous and high-quality services to ensure that messages are promptly replied.

Buy our products and enjoy a year-round worry-free warranty protection.

A forklift laser guide is a safety and precision tool used in forklift operations to assist operators in accurately aligning the forklift forks with the load they are handling.

Laser guided forklift systems project a laser line or beam that helps operators align the forklift forks with pallet slots or rack beams, ensuring precise placement and reducing the risk of damage to goods and equipment.

Accurate fork placement minimizes the risk of damaging goods, pallets, and racking systems, leading to lower repair and replacement costs.

Please fill out the contact form below and we will contact you as soon as possible