Abstract: Forklift zone warning lights are an efficient anti-collision safety tool in industrial environments. They project a bright line on the floor around the forklift to form a designated pedestrian "restricted area". This article aims to help buyers and readers better understand forklift zone warning lights through a comprehensive discussion of the functions, types, advantages, application scenarios, and selection of forklift zone warning lights.

Table of Contents

1. Understand forklift zone warning lights

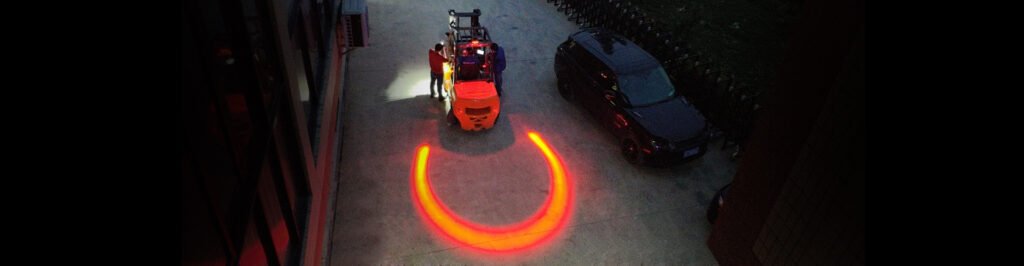

Forklift zone warning lights are a vital safety tool designed to create a clearly visible perimeter around a forklift, ensuring pedestrians maintain a safe distance. These lights are typically red and project a bright line on the floor around the forklift, creating a designated pedestrian "no-go zone". This area is often referred to as a HALO zone, and its distance can be adjusted to meet specific safety requirements.

2. Function of forklift zone warning lights

2.1 Enhanced security

Forklift zone warning lights play a vital role in a warehouse’s overall safety protocol. Bright red lines projected onto the floor create a visible barrier that communicates restricted areas to pedestrians, greatly improving workplace safety. These lights complement other safety measures, such as training programs and signage, by providing continuous, clear visual cues that reinforce the importance of maintaining a safe distance from operating forklifts. The psychological impact of these visual warnings cannot be overstated; knowing that clear, defined safety zones exist helps workers feel safer, which in turn creates a safer work environment.

2.2 Remind pedestrians

Red Zone Lights act as an active warning system for pedestrians, clearly indicating the presence and boundaries of an operating forklift. This real-time visual alert system is particularly useful in noisy environments where verbal warnings may not be heard. The visibility of these lights is effective in a variety of lighting conditions, from well-lit areas to dimly lit corners of a warehouse. By providing a clear visual signal, these lights increase pedestrian awareness, ensuring people maintain a safe distance even in busy or cluttered workspaces.

2.3 Preventing Collisions

One of the key functions of forklift zone warning lights is to prevent collisions, especially rear-end collisions involving forklifts and pedestrians. The red zone creates a clearly visible boundary that helps delineate safe areas, reducing the likelihood of pedestrians getting too close to moving machinery and causing an accident. By clearly marking danger zones, these lights help prevent foot injuries and other accidents in high-traffic areas. Their effectiveness is particularly evident in areas with heavy forklift activity, where the risk of accidental contact is higher.

2.4 Visual warnings

The visual warning provided by the forklift zone warning light is a critical safety feature. The crisp, bright lines projected onto the floor are difficult to miss, providing pedestrians with an instant visual cue that a forklift is present and that they need to keep their distance. This visual indication is essential for avoiding danger zones, especially in environments where forklifts are moving frequently. The constant visual reminder helps prevent accidental entry into danger zones, protecting pedestrians and operators.

2.5 Operational Safety

By establishing clear safety boundaries, forklift zone warning lights significantly improve operational safety. Forklift operators benefit from defined zones because they can navigate busy work areas with greater confidence, knowing pedestrians will be visually warned to keep a safe distance. This extra layer of safety helps prevent accidents, allowing operators to focus more on their tasks without having to constantly worry about pedestrian distractions. These lights are a practical tool to improve operational flow and safety in warehouses.

2.6 Compliance

Forklift zone warning lights also help facilities comply with various safety regulations, such as those set by OSHA. These lights provide a consistent and clear way to delineate safety zones around forklifts, meeting regulatory requirements for workplace safety. By incorporating these lights into safety procedures, facilities can reduce liability and insurance costs because they demonstrate a proactive approach to reducing workplace hazards. Complying with safety regulations not only protects employees, but also enhances a business’ reputation as a safe and responsible employer.

3. Types of forklift zone warning lights

3.1.1 Definition of U-shaped area lights

U-shaped zone warning light project a U-shaped boundary around the front, sides and rear of the truck. This configuration is particularly effective in environments where the truck needs to be maneuvered frequently and where there is a lot of pedestrian traffic.

3.1.2 Specific use cases:

Maneuvering in Confined Areas: U-shaped zone warning light are particularly useful in tight spaces where the forklift needs to maneuver frequently. Full coverage helps prevent accidents by clearly marking the forklift’s operating area.

Corners and narrow aisles: In environments with many corners and narrow aisles, U-shaped projections can improve visibility and ensure that pedestrians can see the safe zone from multiple angles.

3.1.3 Unique Features

Full Coverage: The U-shaped zone warning light provide a 360-degree safety zone, covering the front, sides and rear of the forklift. This feature ensures pedestrians are warned of the forklift's presence from all angles.

Adjustable distance: The distance of the projected U-shaped border can be adjusted to suit specific safety needs, allowing for flexible use in different work environments.

High Visibility: These lights are usually bright and highly visible, ensuring that the safety zone can be clearly seen even in low-light conditions.

3.1.4 Advantages of using U-shaped zone warning light

Enhanced safety: 360-degree coverage ensures pedestrians are aware of the forklift’s presence from all directions, reducing the risk of accidents.

Better navigation for operators: Forklift operators can operate with greater confidence, knowing that the U-shaped lights provide clear warnings to pedestrians around the entire forklift.

Adaptable: These lights can be adjusted to the specific layout of the workspace, providing a customized safety solution.

3.2.1 Differentiating between red zone hazard lights and standard forklift lights

Red Zone Hazard Lights are specifically designed to enhance safety by projecting a red light onto the floor, creating a visible safety zone around the forklift. Unlike standard forklift lights, which primarily illuminate the area in front of the forklift for better visibility during operation, red zone lights serve a different purpose. They are designed to mark the danger zone around the forklift, alerting pedestrians and other workers to keep a safe distance.

3.2.2 Specific Design Elements to Enhance Visibility

Red Zone Hazard Lights incorporate several design elements that enhance their visibility and effectiveness.

Bright Red Light: Red was chosen because it is universally associated with danger and caution. Bright red light is highly visible and stands out against most backgrounds, making it effective in a variety of lighting conditions.

Wide beam angle: These lights typically have a wide beam angle to ensure the projection area is wide and clearly visible from multiple angles. This helps create a large and obvious safety zone around the forklift.

High Brightness: Red Zone Lights are designed to be very bright, ensuring that safe zones remain visible even in brightly lit environments. High brightness makes the lights effective in warehouses with high ambient light levels.

3.2.3 Role in creating a safer operating environment

Enhanced Pedestrian Awareness: A clear, bright red zone projected onto the floor constantly reminds pedestrians to stay away from the forklift’s operating area. This is especially important in a busy warehouse where forklifts and pedestrians often share the same space.

Accident Prevention: By clearly delineating the danger zone around a forklift, these lights help prevent collisions and accidents. Workers are less likely to inadvertently enter the danger zone, reducing the risk of being hit by a forklift.

Comply with safety regulations: Implementing red zone hazard lights helps facilities comply with safety regulations, such as those established by OSHA. These lights demonstrate a commitment to workplace safety and can reduce liability and insurance costs.

Psychological impact: Clearly marked danger zones can have a positive psychological impact on workers. Knowing that there are obvious safety measures in place can make workers feel safer, leading to a safer and more productive work environment.

4. Advantages of forklift zone warning lights compared to other forklift safety lights

Enhanced Visibility: Bright red lines projected onto the floor are clearly visible, even in well-lit environments, ensuring pedestrians can easily identify hazardous areas.

Adjustable Distance: The flexibility of adjustable projected light distance allows for customization to specific safety requirements and workspace layout.

Complete coverage: Unlike blue spotlights that only indicate the presence of a forklift, zone warning lights create clear boundaries, providing better protection for pedestrians.

Operational Efficiency: By clearly marking safe areas, these lights help streamline operations, allowing forklift operators to work more confidently and efficiently without worrying about pedestrian interference.

5. Step-by-step guide to installing forklift zone warning lights

Gather tools and equipment: Make sure you have a forklift area warning light kit, mounting brackets, screws, a drill, and a measuring tape.

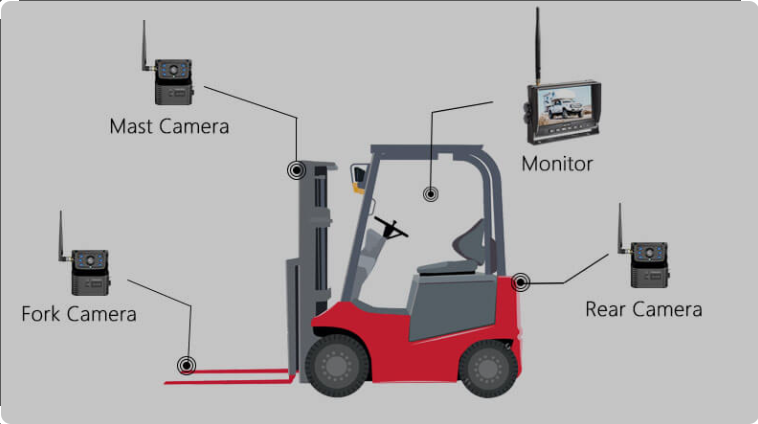

Choose the installation location: Choose a suitable location on the forklift to install the lights. Typically, these lights are located on the side, front, and rear of the forklift.

Measure and Mark: Measure and mark where the lights will be mounted to ensure they are at the correct height and angle for optimal visibility.

Install the mounting bracket: Use a power drill to attach the mounting bracket to the forklift.

Install the lights: Attach the warning lights to the brackets, making sure they are securely in place.

Connect Power: Connect the light to the forklift's power supply. Make sure all connections are secure and insulated.

Test Lights: Turn on the forklift and test the lights to ensure they project the intended boundary lines. Make adjustments as needed.

Final Adjustments: Make final adjustments to the angle and distance of the lights to achieve the desired safe zone.

6. Application scenarios of forklift zone warning lights

6.1 Warehouse

6.1.1 Specific advantages

Red Zone Warning Lights provide a significant safety enhancement in warehouse environments. Warehouses typically have a high volume of pedestrian traffic and forklift activity, so having clear safety measures in place is critical. These lights create a visible boundary around the forklifts, helping to delineate pedestrian safety areas and forklift operating areas.

6.1.2 Managing Pedestrian Traffic

In a busy warehouse environment, red zone lights help manage pedestrian traffic by providing a constant visual reminder of where it is safe to walk. This is particularly useful in areas where space is limited and the risk of accidents is high. These lights ensure pedestrians stay out of the path of moving forklifts, reducing the likelihood of a collision.

6.1.3 Case Study

Amazon fulfillment centers: Amazon has implemented red zone warning lights at several of its fulfillment centers to improve safety. These lights help manage the flow of workers and forklifts, reducing accidents and improving overall efficiency.

Walmart Distribution Centers: Walmart has also adopted red zone warning lights in its distribution centers. These lights are essential to maintain safety standards, especially during peak hours when pedestrian and forklift traffic density is high.

6.2 Construction Site

6.2.1 Necessity

Construction sites are inherently dynamic and dangerous environments, with many moving vehicles, machinery and workers. In these conditions, the use of red zone lights is essential to improve safety. They provide clear and visual warning of danger zones around forklifts, helping to prevent accidents and injuries.

6.2.2 Improve security

Red Zone Lights significantly improve safety on construction sites by creating a visual barrier to alert workers to moving forklifts. This is especially important in areas with poor visibility or during nighttime operations. These lights help ensure workers stay a safe distance from mobile equipment, reducing the risk of accidents.

6.2.3 Adaptability

These lights are highly adaptable and can be used with all types of construction equipment, not just forklifts. Whether on an excavator, loader or other heavy machinery, red zone lights are a versatile safety solution that increases visibility and awareness on construction sites.

6.3 Loading and unloading dock

-1024x266.jpg)

6.3.1 Role in Operations

Loading docks are busy areas where goods are constantly being loaded and unloaded from trucks and trailers. In these environments, the use of red zone lights is critical to ensure the safety of forklift operators and pedestrians. These lights create a clear boundary that helps prevent accidents during loading and unloading activities.

6.3.2 Accident prevention

Red zone lights help prevent accidents at loading docks by providing a clear visual indication of the forklift operating area. This is especially important during loading and unloading, when the risk of collisions between forklifts and workers is high. These lights ensure that everyone in the vicinity is aware of the forklift's presence and can take appropriate precautions.

6.3.3 Importance of Clear Communication

At loading docks, clear communication between operators and pedestrians is essential to maintaining safety. Red Zone Lights accomplish this by providing clear visual signals that can be easily understood by everyone on the dock. This helps coordinate actions and prevents misunderstandings that could lead to accidents.

7. Use forklift zone warning lights to prevent pedestrian accidents

7.1 Strengthen workers’ awareness and training of forklift area warning lights

Workers’ awareness:

The effectiveness of red zone warning lights depends heavily on worker awareness and understanding. Employees must recognize the importance of these lights and understand the boundaries they define. Worker awareness ensures that everyone in the workplace knows to stay out of the red zone, reducing the risk of pedestrian accidents involving forklifts.

training program:

Identification: Teach workers how to identify red zones and understand their purpose.

Behavioral training: Instructing safe behaviors, such as always staying outside the red zone when the forklift is operating.

Scenario-based drills: Conduct drills and simulations to practice real-life situations where workers must react quickly to avoid entering hazardous areas.

Management:

Policy implementation: Develop clear policies regarding the use of red zone lights and adherence to safety protocols.

Regular Audits: Conduct regular safety audits to ensure that lights are functioning properly and employees are following safety guidelines.

Safety Meetings: Hold regular safety meetings to discuss the importance of red zone lights, share updates, and address any issues.

7.2 Case Study

Amazon Fulfillment Centers:

Amazon has successfully implemented red zone warning lights in several of its distribution centers. These lights have significantly reduced the number of pedestrian accidents. The bright red lines clearly delineate safe zones, making it easier for employees to avoid dangerous areas. After installation, Amazon reported a significant reduction in near miss incidents and an improvement in overall warehouse safety.

FedEx Distribution Center:

FedEx installed red zone warning lights throughout its busy distribution centers. Results showed a significant reduction in pedestrian collisions with forklifts. The implementation process included extensive training sessions to ensure all employees understood the importance and function of the red zone lights. Feedback from employees showed an increase in confidence in navigating work areas safely.

result:

Fewer accidents: Both Amazon and FedEx saw a significant decrease in pedestrian accidents and near-accidents.

Improved efficiency: Clear demarcation of safety zones helps streamline operations as workers are more aware of their surroundings and can better coordinate with forklift operators.

Positive employee feedback: Workers say they feel safer and more confident knowing visual safety measures are in place.

Employee Testimonials:

Amazon employee: "Since installing the red zone lights, I have noticed a significant improvement in our safety. It is now easier to see where it is safe to walk, especially during busy shifts."

FedEx Employee: "The red zone light has made a huge difference. I feel safer knowing there are clear boundaries, and it helps me focus on my job without having to worry about the forklift all the time."

8. Maintenance of forklift zone warning lights

Regular Cleaning: Keep the lamp and lens clean to ensure maximum visibility. Dust and debris will reduce the effectiveness of the lamp.

Check the connections: Regularly check electrical connections for signs of wear or damage. Make sure all wires are secure and insulated.

Check alignment: Check the alignment of the lights regularly to ensure they are projecting the correct boundary lines. Make adjustments as needed.

Replace light bulbs: If you use traditional light bulbs, replace them as soon as they start to dim or flicker. LED lights generally last longer, but should still be checked regularly.

Monitor Performance: Test your lights regularly to make sure they are working properly. Resolve any issues immediately to stay safe.

9. Selection of forklift zone warning lights

Environment: Consider the lighting conditions and layout of your workspace. Brighter environments may require more powerful lights.

Forklift Type: Make sure the light is compatible with your specific forklift model.

Safety needs: Assess pedestrian traffic levels and specific safety requirements for the workplace.

Durability: Choose lights that are durable and able to withstand environmental operating conditions, including exposure to dust, moisture, and vibration.

Regulatory compliance: Make sure the lights comply with any relevant safety regulations and standards, such as those set by OSHA.

10. Common Problems with Using Forklift Zone Warning Lights

10.1 Which color should I choose for my forklift zone warning lights?

The most common color for forklift area warning lights is red, as it is universally recognized as a warning color. However, certain environments may benefit from other colors, such as blue or green, depending on visibility needs and specific safety protocols.

10.2 How far away is the red light usually from the forklift?

The distance of the red light from the forklift is usually adjustable. A common setting is 2 to 3 feet from the forklift, creating a clear safety perimeter without interfering with operations. This can be adjusted based on the specific layout and safety requirements of the workspace.

10.3 What are OSHA’s regulations regarding lighting?

OSHA has specific regulations for workplace lighting, including visibility and safety requirements for areas where heavy machinery is operated. Forklift area warning lights help comply with OSHA standards by improving visibility and reducing the risk of accidents. OSHA emphasizes the importance of adequate lighting to ensure safe operations and prevent accidents.

10.4 Do red zone hazardous area warning lights meet UL rating requirements?

Currently, Red Zone lights are UL listed for regular forklifts as well as EE and LPS class forklifts. This means they can be installed on any regular forklift, as well as EE and LPS class forklifts, but not EX class forklifts. They will never be rated for EX trucks for use in high hazardous locations.

10.5 What types of forklifts can red zone danger area warning lights be used for?

Red Zone lights are designed for any forklift that is primarily used indoors. They can be used on any type of forklift including sit-down forklifts, stand-up forklifts, tractor trolleys, and more. If you are going to use them on manned forklifts such as pickers and turret trucks, purchase a set to try before ordering for your fleet to ensure they will work at your height and in your specific application. Red Zone lights can be used on any fuel type including but not limited to propane, gasoline, diesel, natural gas, electric, and more. While Red Zone lights are weatherproof and can be taken outside, they are not bright enough to be effective outdoors on a sunny day. They will be more effective outdoors at dusk, dawn, or at night.

11. Summary

Forklift zone warning lights are an effective anti-collision application that creates a visible boundary around the forklift to ensure pedestrians maintain a safe distance. These lights can improve visibility, improve operational efficiency, and help comply with safety regulations. Currently, more and more buyers see the advantages of forklift area warning lights and apply them in industrial environments, greatly reducing the rate of forklift accidents.

-1024x683.jpg)