Forklifts are integral to the smooth operation of warehouses, distribution centers, and construction sites. However, operating a forklift can pose significant safety risks, not only for the driver but also for pedestrians, other operators, and nearby equipment. To mitigate these risks and ensure a safer working environment, many businesses are turning to advanced forklift camera systems. These systems offer a comprehensive way to monitor blind spots, improve visibility, and reduce accidents, all while enhancing overall operational efficiency.

In this article, we will explore the various aspects of forklift camera systems, including their functionality, benefits, different safety solutions, and how to choose the right system for your needs.

1. What is a Forklift Camera System?

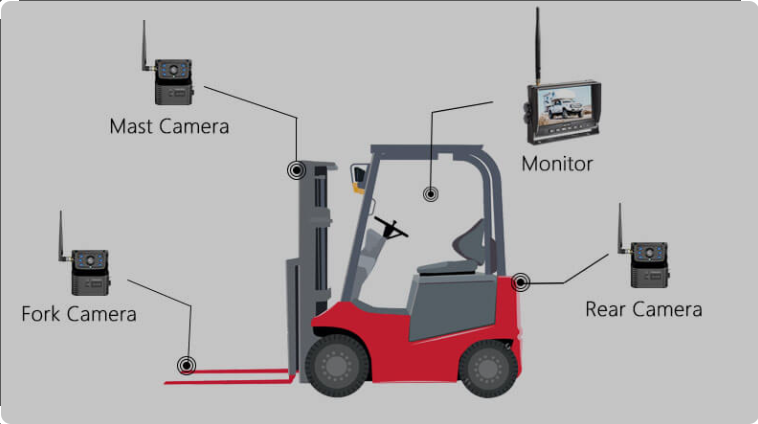

A forklift camera system is a set of integrated cameras and sensors installed on a forklift to provide real-time video feeds to the operator. These systems help eliminate blind spots and improve visibility around the forklift, allowing operators to navigate more safely and effectively in crowded or hazardous environments.

A typical forklift with camera setup includes one or more cameras mounted on the vehicle, usually on the rear, front, or sides. These cameras capture live video, which is displayed on a monitor inside the cabin. In addition to enhancing visibility, forklift camera systems often come with additional safety features like audio alerts, collision sensors, and other warning systems.

Types of Forklift Camera Systems:

- Forklift Reversing Camera: Specifically designed to help operators see behind them when reversing, this type of camera is one of the most commonly installed safety features.

- Forklift Blind Spot Camera: Provides visibility into hard-to-see areas around the forklift, reducing the risk of accidents.

- 360° Forklift Camera System: Uses multiple cameras positioned around the forklift to offer a complete, bird’s-eye view of the surroundings.

2. How Does a Forklift Camera System Work?

.png)

A forklift camera system typically works by using a combination of cameras and video processing technology to display real-time footage to the operator. The system works as follows:

Cameras: Cameras are installed at key positions on the forklift, such as the front, rear, sides, or even under the chassis. These cameras are usually ruggedized and designed to withstand harsh warehouse or industrial environments.

Monitor/Display: Inside the forklift cabin, a monitor is installed where the operator can view the live feed from the cameras. The monitor can be mounted on the dashboard or near the steering wheel for easy visibility.

Camera Switching: Depending on the system’s complexity, the camera system may switch between different cameras automatically or allow the operator to manually switch between views. For example, when reversing, the system may automatically display the forklift reversing camera, while driving forward, the system may switch to the front view.

Audio Alerts and Sensors: Some systems come with additional features such as audio warnings or collision sensors. These features alert the operator to potential dangers, such as obstacles in their path, or when the forklift is too close to another object.

Recording and Data Logging: Advanced forklift camera systems may also record video footage for later review. This can be useful for training purposes, accident investigations, or general operational review.

By offering better visibility and reducing the need for the operator to turn their head or rely on mirrors, forklift cameras significantly enhance the safety of the operator and those around them.

3. Why Invest in Forklift Safety Cameras?

Forklift accidents are among the most common causes of injury in warehouses, distribution centers, and construction sites. According to the Occupational Safety and Health Administration (OSHA), forklift accidents cause thousands of injuries and fatalities each year. By investing in a forklift camera system, companies can reduce these risks and protect their employees, assets, and the overall work environment.

Key Reasons to Invest in Forklift Camera Systems:

- Improved Safety: The primary benefit of a forklift camera system is enhanced safety. With better visibility, operators can avoid collisions with pedestrians, other vehicles, and obstacles in the workplace.

- Increased Productivity: By reducing the likelihood of accidents and improving efficiency, forklift camera systems can help improve overall productivity. Operators spend less time maneuvering cautiously and more time efficiently performing tasks.

- Compliance with Safety Standards: Many industries require businesses to meet specific safety standards. Installing a forklift camera system can help your company comply with OSHA or other regulatory bodies’ safety regulations.

- Reduced Liability: A forklift camera system can help prevent accidents and provide valuable video evidence in case of disputes or insurance claims. It can also help track performance and highlight areas that require attention.

- Reduced Damage to Equipment: With improved visibility, forklift operators are less likely to damage goods, vehicles, or equipment, leading to lower repair costs and fewer product losses.

4. Benefits of Forklift Camera Systems for Logistics Leaders

In industries like logistics, where warehouses are often bustling with activity, the benefits of forklift safety cameras extend beyond just the individual operator. Logistics leaders can also benefit significantly from these systems.

Key Benefits for Logistics Leaders:

- Enhanced Operational Efficiency: By ensuring better visibility and reducing accidents, forklift camera systems help create a smoother flow of goods in warehouses and distribution centers. This leads to fewer delays, faster handling, and greater efficiency.

- Real-time Monitoring: Forklift camera systems can be integrated with warehouse management software, enabling real-time monitoring of forklift activity. Logistics managers can oversee forklift movement, track performance, and address any issues promptly.

- Reduced Risk of Liability: In case of accidents or disputes, having video footage from the forklift camera system can provide evidence that protects the business from liability claims.

- Better Training and Evaluation: New forklift operators can benefit from having access to recorded footage of their driving, allowing managers to offer more effective training and performance evaluations.

5. What Are the Different Forklift Safety Solutions?

In addition to forklift camera systems, there are various other safety solutions available to ensure forklift operators work in a safe environment. Here are some of the most common and effective forklift safety features:

5.1 Forklift Blue Light and Forklift Red Light

-600x499.jpg)

Forklift Blue Light and forklift red light are warning lights that enhance visibility and alert pedestrians or other workers to the presence of a forklift. The blue light projects a visible beam on the ground, often used in combination with the red light, which projects an alert to the presence of the forklift.

- Forklift Blue Light: Used to alert people when the forklift is moving in reverse. The blue light creates a visual warning on the floor to signal to pedestrians to stay clear of the forklift’s path.

- Forklift Red Light: Typically used when the forklift is operating in forward motion. The red light provides a warning that a forklift is nearby and should be avoided.

Both of these safety lights help to prevent accidents by alerting individuals to the forklift’s presence in low visibility conditions.

5.2 LED Warning Light

-600x600.jpg)

An LED warning light is often installed on forklifts to give a visible signal of operation or danger. These lights are designed to be visible even in noisy or busy environments, such as warehouses and construction sites. They help to make forklift operators more visible to others, reducing the chances of collisions.

5.3 LED Sign Projector

An LED sign projector is another innovative safety solution. It projects a company logo or safety warning message on the ground near the forklift. This serves as an additional visual cue to alert pedestrians or other operators to the presence of a forklift, especially in dimly lit or crowded areas.

5.4 Virtual Line Projector

-1024x266.jpg)

A virtual line projector projects a virtual line on the ground, creating a visual boundary that forklifts should not cross. This system can be used to separate pedestrian walkways from forklift routes or to set up safety zones in a warehouse. The projector creates a clear, visual warning to help prevent accidental collisions and improve warehouse layout safety.

5.5 Forklift Camera System

The forklift camera system, as discussed earlier, is an essential safety feature for improving visibility around the forklift and reducing the risks of accidents. It is often used in combination with the other safety features like the forklift blue light, LED warning light, and virtual line projector.

6. Features of Different Forklift Camera Systems

When selecting a forklift camera system, it’s important to consider the specific features that will best suit your operational needs. Some of the key features to look for include:

- Wide-Angle Cameras: Cameras with wide-angle lenses provide a larger view of the surroundings, reducing blind spots.

- Infrared or Night Vision: Some forklift camera systems include infrared technology to provide clear footage in low-light conditions.

- Waterproof and Shockproof Design: Since forklifts operate in harsh environments, it’s crucial to select cameras that are rugged and built to withstand exposure to dust, water, and vibrations.

- Multiple Camera Options: Depending on the forklift’s use, multiple camera views (front, rear, side, or 360-degree coverage) may be required for optimal visibility.

- Monitor Integration: The system should have a monitor that is easy for operators to view without distraction. Some systems even offer split-screen displays for multiple camera views.

7. How to Choose the Right Forklift Safety System Supplier

Choosing the right supplier for your forklift camera system is essential for ensuring that you get a quality, reliable product. Here are some tips for selecting the right supplier:

- Experience and Reputation: Look for a supplier with a proven track record in the forklift safety industry.

- Customization Options: Some businesses may have specific needs depending on the size of the warehouse or the number of forklifts in operation. Choose a supplier that offers customizable camera systems.

- Support and Service: Ensure that the supplier offers good customer support, installation services, and after-sales maintenance.

- Compliance with Safety Standards: Ensure the camera system complies with OSHA and other relevant safety standards.

8. Conclusion

Forklifts play a vital role in modern warehouses and distribution centers, but they also come with safety risks. Investing in a forklift camera system is one of the most effective ways to enhance safety, improve visibility, and reduce the chances of accidents. Whether you’re looking for a forklift reversing camera, a 360-degree camera system, or additional features like LED warning lights, there are numerous options available to improve forklift safety in your warehouse. By choosing the right forklift safety solutions and camera systems, you can significantly reduce the risk of accidents, protect your workers, and improve the overall efficiency of your operations.

-1024x683.jpg)