Summary: LED warning lights play a vital role in maintaining workplace safety, especially for emergency vehicles and industrial operations. Compliance with Occupational Safety and Health Administration (OSHA) standards is key to ensuring that workplaces are not only safe but also legal. In this article, we will explore the importance of LED warning lights relative to OSHA lighting requirements, their advantages over traditional lighting systems, and the essential features to consider when selecting the best LED lights.

1. OSHA Lighting Requirements

Ensuring workplace safety involves adhering to several OSHA regulations, particularly for environments where visibility and proper lighting are critical. LED warning lights are a significant component of meeting these standards in various industries.

1.1 Overview of OSHA Requirements

OSHA mandates certain regulations to safeguard workers, especially in environments where vehicles, such as forklifts, are in operation. Proper lighting is essential for accident prevention, and non-compliance can result in fines, accidents, and injuries. Emergency vehicle lighting is specifically governed under OSHA guidelines, which emphasize:

- Adequate visibility for workers operating machinery or vehicles.

- Lighting levels sufficient to ensure that people and objects can be seen from a distance.

- Warning systems for moving vehicles to alert pedestrians.

Failure to comply with these guidelines can compromise workplace safety and lead to legal consequences.

1.2 The Role of LED Retrofits in Meeting OSHA Standards

Many companies are turning to LED retrofits to update outdated lighting systems and meet OSHA standards. Retrofits involve replacing traditional lighting with more energy-efficient and brighter LED lights, which are better suited for providing clear visibility in industrial settings. This transition helps companies avoid potential fines from OSHA, while simultaneously improving safety.

1.3 The Role of LED Warning Lights in OSHA Compliance

LED warning lights, with their high brightness and durability, are ideal for helping businesses remain OSHA-compliant. These lights ensure that:

- Vehicles are visible in poorly lit or adverse weather conditions.

- Workers are alerted to moving machinery, reducing the risk of accidents.

- Operations continue smoothly, without frequent breakdowns or replacements, helping to avoid non-compliance issues.

Investing in OSHA-approved LED warning lights can help prevent accidents and ensure the business stays compliant with safety regulations.

2. Understanding LED Warning Lights

LED warning lights are gaining popularity due to their effectiveness, longevity, and compliance with modern safety standards. Understanding their purpose and advantages over traditional lighting systems is key to choosing the best solutions for your business.

2.1 Basic Definition and Purpose

LED warning lights are high-intensity lighting systems designed to alert workers, pedestrians, or other vehicles of potential dangers. These lights are used across various industries, from emergency vehicles to construction sites and industrial warehouses, where visibility and safety are paramount.

Their main purposes include:

- Alerting personnel to the presence of moving vehicles.

- Creating visual boundaries to guide workers and operators in confined spaces.

- Enhancing visibility during operations in low-light conditions.

2.2 Common Applications

LED warning lights are utilized in a wide range of applications, including:

- Emergency vehicles: Ambulances, fire trucks, and police cars rely on LED warning lights for quick response in emergencies.

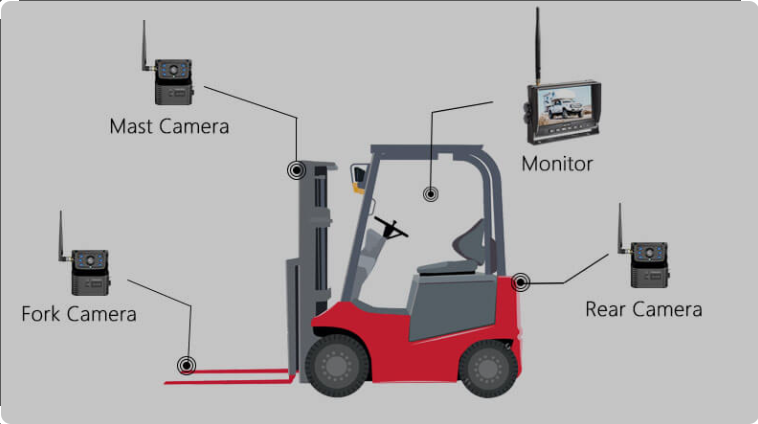

- Forklifts: Industrial environments use LED lights to signal forklift operations, reducing the risk of collisions with pedestrians.

- Construction equipment: Heavy machinery often uses LED warning lights to ensure visibility in construction zones, especially in low-light conditions.

2.3 Benefits Over Traditional Lights

When compared to traditional incandescent or halogen lights, LED warning lights offer several advantages:

- Brighter illumination: LEDs provide more intense and focused light, making them more effective in alerting workers and pedestrians.

- Energy efficiency: LEDs consume significantly less energy, making them both environmentally friendly and cost-effective.

- Longer lifespan: With a lifespan of up to 50,000 hours, LED lights far outlast traditional lighting systems, reducing the need for frequent replacements.

3. Key Features to Consider When Choosing LED Warning Lights

Choosing the right LED warning lights for your business requires consideration of several important factors that impact performance, safety, and cost.

3.1 Brightness and Visibility

The brightness of LED warning lights is a key feature that sets them apart from other lighting systems. LED technology allows for greater intensity, making the lights more visible over long distances and in poor weather conditions. High visibility is crucial for preventing accidents, especially in industrial settings where heavy machinery is in use.

Key considerations include:

- LED optics: These control how light is distributed, ensuring that it covers a wide area.

- Visibility distance: LED lights can be seen from a greater distance than traditional lights, reducing the chance of collisions or accidents.

In adverse weather conditions, such as fog, rain, or snow, bright warning lights are essential to ensure that vehicles are visible to other drivers and pedestrians.

3.2 Energy Efficiency

One of the major benefits of LED warning lights is their energy efficiency. These lights consume significantly less power than traditional lighting systems, which leads to several advantages:

- Reduced operational costs: Lower energy consumption means lower utility bills, which is particularly important for companies with large fleets of vehicles.

- Environmental benefits: Using energy-efficient LEDs reduces the carbon footprint of a business, contributing to a more sustainable operation.

Energy savings also extend the battery life of vehicles, making LED lights an eco-friendly and cost-effective solution for long-term use.

3.3 Durability and Lifespan

LED warning lights are designed to withstand the harsh conditions often encountered in industrial and emergency settings. They are built to endure:

- Extreme temperatures: Whether exposed to freezing cold or scorching heat, LED lights continue to function without degradation in performance.

- Shock and vibration: Forklifts and emergency vehicles can generate intense vibrations that could damage traditional lighting systems. LED lights are rugged and resistant to these forces.

The long lifespan of LED lights, often reaching up to 50,000 hours, also means fewer replacements and reduced maintenance costs. This durability makes them a cost-effective investment in the long run.

3.4 Strength of LED warning light manufacturers

When choosing LED warning lights, it is crucial to consider the strength of the manufacturer. Xinruilai Lighting Company has been deeply involved in the forklift lighting industry for more than 20 years and has accumulated profound experience. LED warning lights are one of its core products. Choose Xinruilai Lighting Company, you will get the following quality services:

●One-year warranty

●No MOQ

●Customizable Logo

● the 24-hour assistance provided by our dedicated support team.

4. How to Maintain and Replace LED Warning Lights

Proper maintenance of LED warning lights ensures that they continue to function efficiently, providing the necessary safety alerts in industrial or emergency environments.

4.1 Routine Maintenance Steps

Maintaining LED warning lights involves a few simple but essential tasks:

- Regular inspections: Check for any physical damage or wear to the lights, wiring, or mounts.

- Cleaning: Ensure that the lenses of the lights remain clean and free from dirt or debris that could obstruct visibility.

- Testing: Periodically test the lights to ensure that they are functioning at full brightness and the flash patterns are working as expected.

4.2 Signs for Replacement

Although LED warning lights have a long lifespan, there are still signs to look out for that indicate it’s time for a replacement:

- Dimming lights: If the lights begin to dim or lose intensity, it may be time to replace them to ensure maximum visibility.

- Flickering or failure: Lights that flicker or fail to turn on consistently should be replaced to maintain safety standards.

4.3 When to Replace

LED warning lights should be replaced when:

- Their brightness is significantly reduced.

- They no longer meet OSHA or safety guidelines for visibility.

- They have sustained physical damage that could impair their effectiveness.

5.Conclusion

Choosing the right LED warning lights for your business not only helps ensure compliance with OSHA lighting requirements but also improves workplace safety. These lights offer a variety of advantages over traditional lighting systems, including superior brightness, energy efficiency, durability, and longevity.

By understanding the importance of these features and how to maintain your lighting systems, you can significantly reduce the risk of accidents in industrial settings, keep operations compliant with OSHA regulations, and ultimately contribute to a safer, more productive work environment.

Investing in high-quality LED warning lights is a cost-effective way to enhance visibility, protect workers, and maintain smooth operations, whether in an industrial warehouse or an emergency response scenario.

-1024x683.jpg)